From Cockermouth to the Cape: The Journey of Mossop Leather

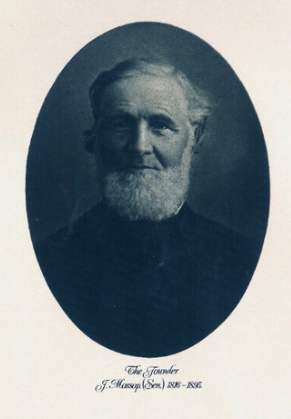

Nestled in the serene Wordsworth country of northern England, the village of Cockermouth saw the birth of a man whose legacy would stretch across continents. Joseph Mossop, the son of a tanner, grew up steeped in the traditions of leather craftsmanship. At the age of 26, Joseph and his wife Mary embarked on a daring journey, setting sail for the southern tip of Africa.

After a brief stint as a schoolteacher in Greyton, Natal, Joseph found his calling once again in Cape Town. There, an opportunity arose to revive the craft of his forebears. On the banks of the Liesbeek River in Rondebosch, he established the foundation for a business that would thrive for over a century. Negotiations with Cape Town merchant John Ebden secured the site on Belmont Road. Interestingly, Ebden's need for capital for a fledgling insurance firm—later known as Old Mutual—paved the way for Mossop's burgeoning enterprise.

"Established as early as 1846, Mossop & Sons set up their first premises in Rondebosch."

The Family Tradition Grows

Joseph's 17-year-old son, Joseph Mossop Jr., joined the business, marking the beginning of a family tradition. In 1874, just a year before Joseph Sr.’s death, control of the company passed to Joseph Jr., who, alongside Ernest Bartholomew Garland, formed the partnership Mossop & Garland. The families, connected through marriage, grew the business steadily. By 1875, the company earned international acclaim, receiving a special medal at the Centennial Exhibition in Philadelphia.

In the late 19th century, Mossop & Garland adapted to challenges with resilience. The devastating Rinderpest epidemic rendered hides scarce, forcing the company to diversify into tanning angora woolskins. The Boer War brought further disruptions, but the company weathered these storms. In 1907, the partnership dissolved, and Mossop & Sons Ltd was reestablished with Joseph Jr. and his son Percy at the helm.

A Legacy of Innovation and Advocacy

As the 20th century dawned, Mossop became a pioneer in chrome-tanned leather production. This innovation, spearheaded by Percy Mossop after studying leather science in England, set a new standard in the industry. The company’s resilience was further tested during periods of economic difficulty, but its reserves and adaptability ensured survival.

Leadership passed to Harold Mossop in 1910, following Percy’s retirement due to ill health. Harold’s vision and expertise positioned the company as a leader in leather exports, introducing South African products to global markets. His efforts extended beyond the business; he played a pivotal role in the Cape Chamber of Industries, serving as its president in the early 1920s.

A Family Tradition of Excellence

The Mossop legacy continued with Harold’s son, Ralph, who joined the firm in 1936. Bringing a modern scientific approach, Ralph established a chemical laboratory to refine tanning processes. During World War II, Mossop Leather contributed significantly to the Allied war effort, producing leather for millions of army boots. By 1957, Ralph succeeded Harold as managing director, maintaining the company’s reputation for excellence and innovation.

Under the leadership of subsequent generations, Mossop Leather faced a rapidly evolving industry. The rise of synthetic materials in the mid-20th century posed significant challenges. However, the company’s commitment to quality and adaptation to market trends allowed it to thrive. In the 1960s, Tony Mossop, equipped with expertise in chrome tanning, led the company into a new era, focusing on side leathers for both local and export markets.